MAGNAS

The standard match ball, the "thermal ball"

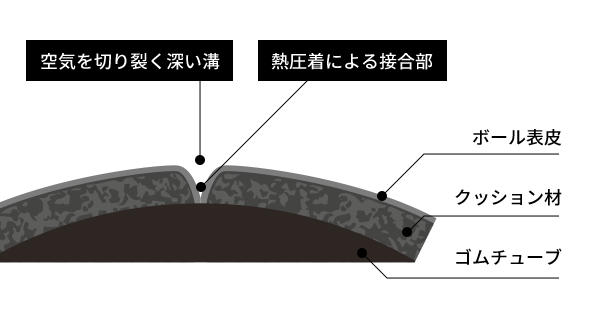

Most of the balls used as match balls in official soccer matches are made using a method called thermal manufacturing, in which panels are pressed together using heat.

The panels are attached directly to the tubes inside the ball without using any thread, so the gap-free joints prevent water from entering and there is no need to worry about the ball becoming heavy even in the rain.

Furthermore, pressure is applied evenly to bond the panel boundaries, resulting in high sphericity, allowing you to kick the ball with the same feeling no matter where you kick it.

A new standard practice and match ball for schools and teams across the country

SFIDA, which has its roots in the manufacture of high-quality, hand-sewn fair trade soccer balls, is challenging the price of thermal balls.

I want to use balls of the same quality as the official balls even during practice!

To support soccer club members and coaches across the country who continue to challenge themselves to achieve their dreams and goals, MAGNAS has achieved the quality of an official match ball at the price range of a practice ball.

Please choose the best ball depending on the environment in which you will be using it.

Hard Ground

Coated surface for improved control and durability with sand prevention valve

TURF GROUND

Embossed for optimal slip resistance and delicate ball touch

SPEC

What is the Magnus effect? = A perpendicular force acting on a rotating object

LINEUP

MAGNAS Earthly Life

MAGNAS for turf

MAGNAS Earthly Life

PHOTO GALLERY

for Business

for Business